Netting

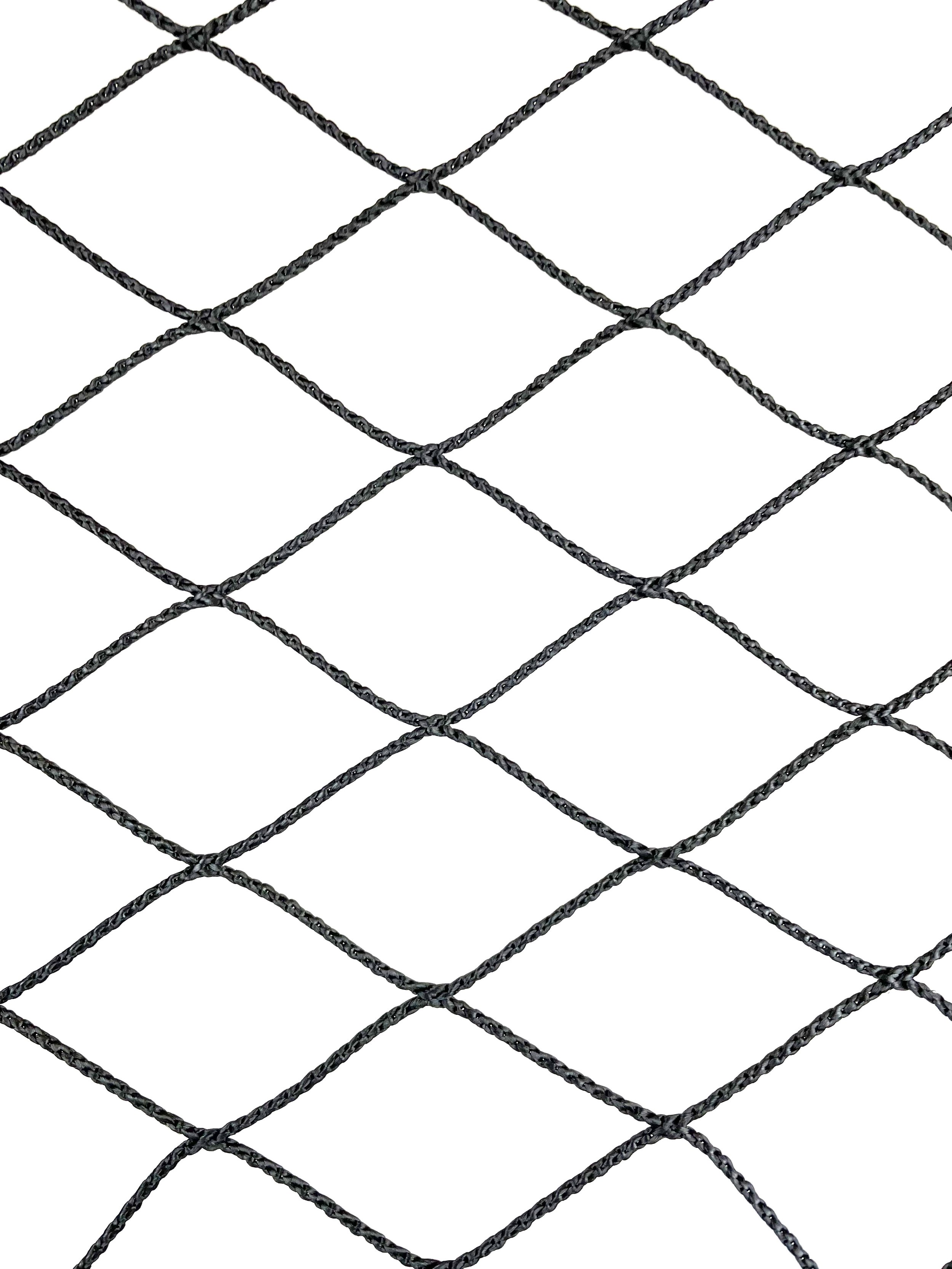

There are two main types of netting: knotted and knotless.

Netting comes in several materials, for use in various applications: Nylon, polyester, polyethylene, UHMWPE (For example Dyneema™ and Spectra™), Vectran, a blend of any of the above, or even biodegradable cotton.

Gannet Nets focuses on UHMWPE (and blends of UHMWPE) Nylon and Polyethylene.

UHMWPE has advantages over nylon, it is significantly stronger and much less weight/volume. In its unblended form it will float which is helpfull when fishing shallow rocky bottom. It has some disadvantages, it’s soft/limp which tends to make it snag on things easily, it will ‘fly’ in the wind, and it’s expensive!

Nylon is a tried and true material, and still a great choice. I am lucky to have Diamond Nets nearby, they have been making excellent nylon netting for decades. Nylon’s only real downside is it has significantly more volume.

View product sheet & spec sheet for salmon netting here, and Twisted Nylon Netting Weight Chart here.

*based on 100 meshed deep x 100 fathoms

The most common purse seine netting is knotted nylon, and this can be twisted (more common), or braided (common for Tuna). In some areas of a purse seine, especially those likely to be on bottom to any extent, polyethylene netting is also used. Polyethylene has two attributes that help when in contact with the bottom, it is stiffer than nylon, and it floats.

Raschel style knotless is generally less expensive than knotted netting, because it is faster to produce than knotted netting. Raschel knotless is similar to knotted netting in strength.

Search Netting By Species:

-

Netting comes in various materials for various applications: Nylon, polyester, polyethylene, UHMWPE (Such as Dyneema™ and Spectra™), Vectran, or even biodegradable cotton.

Gannet Nets focusses on UHMWPE and blends of UHMWPE and Polyester, to make it sink.

Nylon is a tried and true material, and still a great choice. It’s only real downside is it has significantly more volume and weight in the water, which is a disadvantage if sinking speed or wanting to move the net through the water is important. I am lucky to have Diamond Nets nearby, they have been making excellent nylon netting for many years.

-

Twine sizes of knotless:

#8#8S Sinking

#9

#9 Sinking

1.5mm

1.6mm

1.8mm

2.1mm

2.3mm

2.5mm

-

Technically this is excellent netting, I love it’s performance. I don’t use it much because of the disadvantge of taking more time and skill to repair.

Japanese style knotless comes in two types, a twisted knotless construction, sometimes called Twisted Cross or Moketsu, and a braided knotless construction, known as Ultracross or Eurocross.

Japanese style knotless machines were invented in Japan around 1925, later the Japanese invented the machine to make the ultra-cross braided knotless. Japanese style knotless netting has a couple of huge advantages. It is stronger than knotted netting, of the same diameter and raw material, by anywhere from 35% to 55%, this is due to the fact that introducing a knot into any line, or twine, immediately causes a significant loss of strength. Japanese knotless netting has no significant loss of strength. Removing the knots also increases the sinking speed and lowers the water resistance against the netting. This increase in strength over knotted netting of the same twine size, allows you to use thinner twine. Removing all those knots makes for a significant weigh and volume savings, relative to knotted netting of the same material.

There are two main disadvantages to the Japanese style knotless:

The first is the increased expense over knotted netting or raschel knotless netting, and this is because it takes a lot longer to manufacture.

The second is there tends to be more time spent on repairs, especially with the twisted knotless as opposed to braided knotless, which when cut or broken, starts unraveling, making the damage grow quickly if not dealt with. Mending Japanese knotless netting takes more time and requires more skill than mending knotted netting.

-

-

Please get in touch.

2.5mm Treated Black knotless UHMWPE bunt netting

Double Knotted SPB42, 1.6mm Braided prebunt netting, Sinking

Double Knotted 2.3mm SPB72, Braided Bunt netting. Sinking

Knottless 1.5mm UHMWPE border netting, Green/Blue tracer

Knotless 1.8mm UHMWPE leadline chaffing strip, red/yellow tracer

Knotless 8S UHMWPE body web, sinking, yellow tracer